From digital laser cutting to the design of reusable masks, easy to sanitize: this is how architecture firm FOSTER + PARTNERS joins the battle against COVID-19, delivering a free project to the London health organization. In the article, all the specifications and links to download the project.

An emergency situation that redefines the application limits of the architectural project. In this sense, design skills explore different scales, from architectural design for new spaces to products to react to the pandemic. A widespread and multidisciplinary knowledge, a way of designing intended as a "response to a problem" that can be applied to different topics. From the spoon to the city, quoting Ernesto Rogers.

With "tips for a post-coronavirus future", Isplora opens a new section, a catalog of pragmatic solutions to everyday and emergency problems, selecting projects, alternatives, proposals and visions. From the architectural scale to the product scale, from spaces to objects, from prototypes to re-uses, from materials to building techniques that can field architecture in imagining a post-coronavirus future, bringing into play the architects’ practice and versatility, involving the knowledge of designers and the ability of production companies.

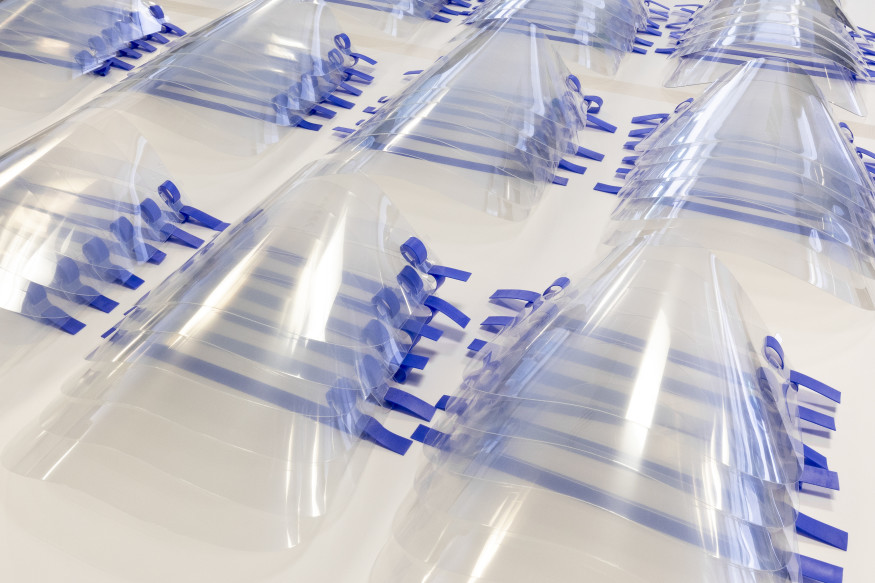

There are numerous examples. The first one we mention is the very recent proposal by Foster + Partners that, with the expansion of the pandemic in the United Kingdom, immediately fielded a heterogeneous team of professionals to design and prototype a mask obtained by digital laser cutting. To counter COVID-19 and join the fast and efficient production of devices for personal protection against infection, the firm in fact designed a prototype "face visor" that can be produced, used, sanitized and reused, aimed at mass production, so that a large number of masks that can be easily made and assembled.

The open-source nature of the project is the key to the proposal

The goal is to encourage both designers and large-scale manufacturers to produce the visors, but also investigate the potential of digital starting from laser cutting. The prototyped visor was designed by a team of industrial designers, as well as experts in physical and digital 3D modeling, architects and analysts. It consists of an optically transparent 0.5 mm PETG visor, an interlocking soft PP headband and a surgical silicone rubber head strap that ties the two together. Each element is designed to be realized with digital laser cut technology, with a production time of less than 30 seconds and less than one minute for assembly. With a single laser cutting machine, it is possible to assemble the components for 1,000 masks a day, representing a significant reduction in the time it would take with 3D-printed alternatives. An important advantage is that the visor can be easily disassembled, cleaned, sanitized and reused. For this reason, Foster + Partners has delivered the prototype visors to several London hospitals, where they are being tested, and is now waiting for answers from the corporate market to provide a method for mass production.

Here is detailed information about the open-source project:

• Click here and download assembly instructions;

• Click here and download the digital file for the laser cutting (.dwg)

OFFICIAL CREDITS

- This design for a flat pack laser cut visor (the Design) is created and owned by Foster + Partners Limited and is licensed for non-commercial use under the Creative Commons Attribution-Non Commercial 4.0 International Public License (https://creativecommons.org/licenses/by-nc/4.0/legalcode#s2b) (“the CCL Terms”).

- As set out in Section 5 of the CCL Terms, no representations or warranties of any kind concerning the Design are given.

- By downloading and or using the Design files, you accept and agree to the CCL Terms and acknowledge that this Design has been created by Foster + Partners in response to the global COVID-19 pandemic; that Foster + Partners has no prior expertise in the design and manufacture of Personal Protective Equipment (PPE) and therefore this Design has neither been made by reference to any specific regulations nor subject to any formal testing regime; that any user of the Design shall assume all responsibility for developing the design in conformity with regulatory and testing requirements of any markets it intends to make the visor available in.